About Luminite Products Corporation

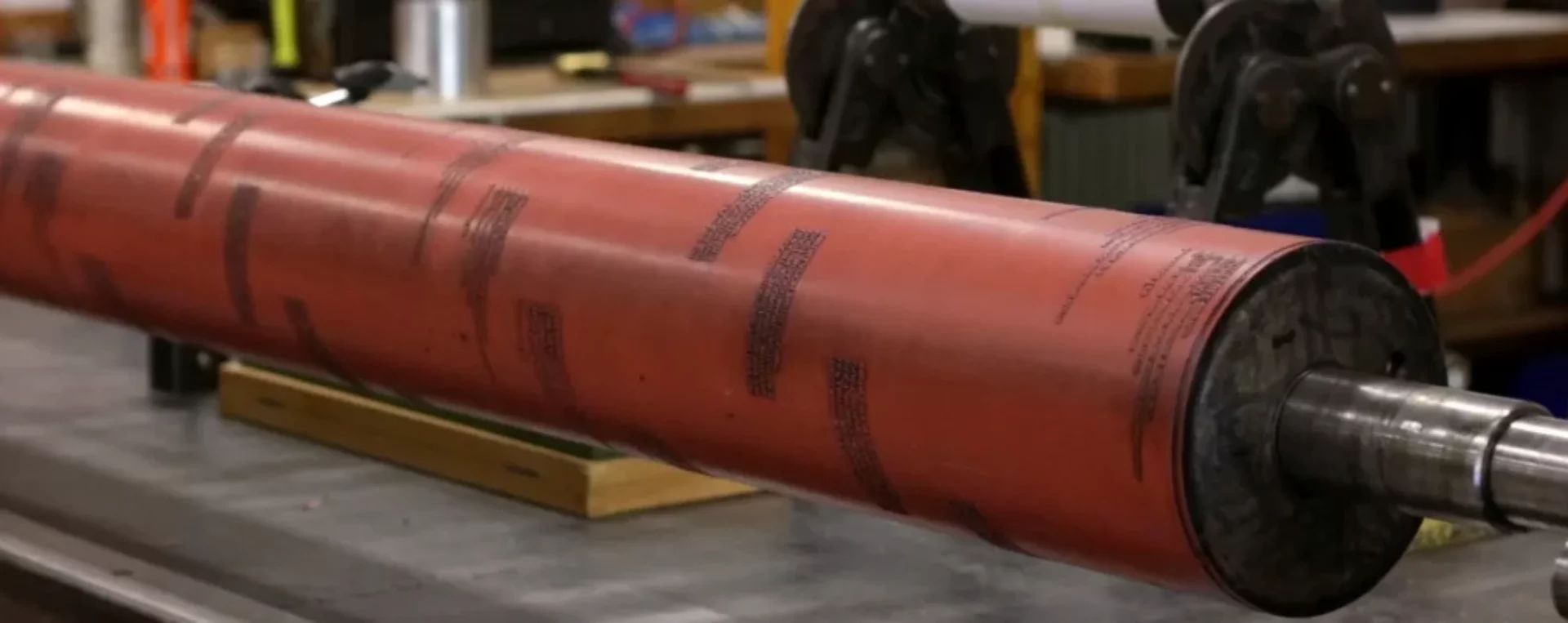

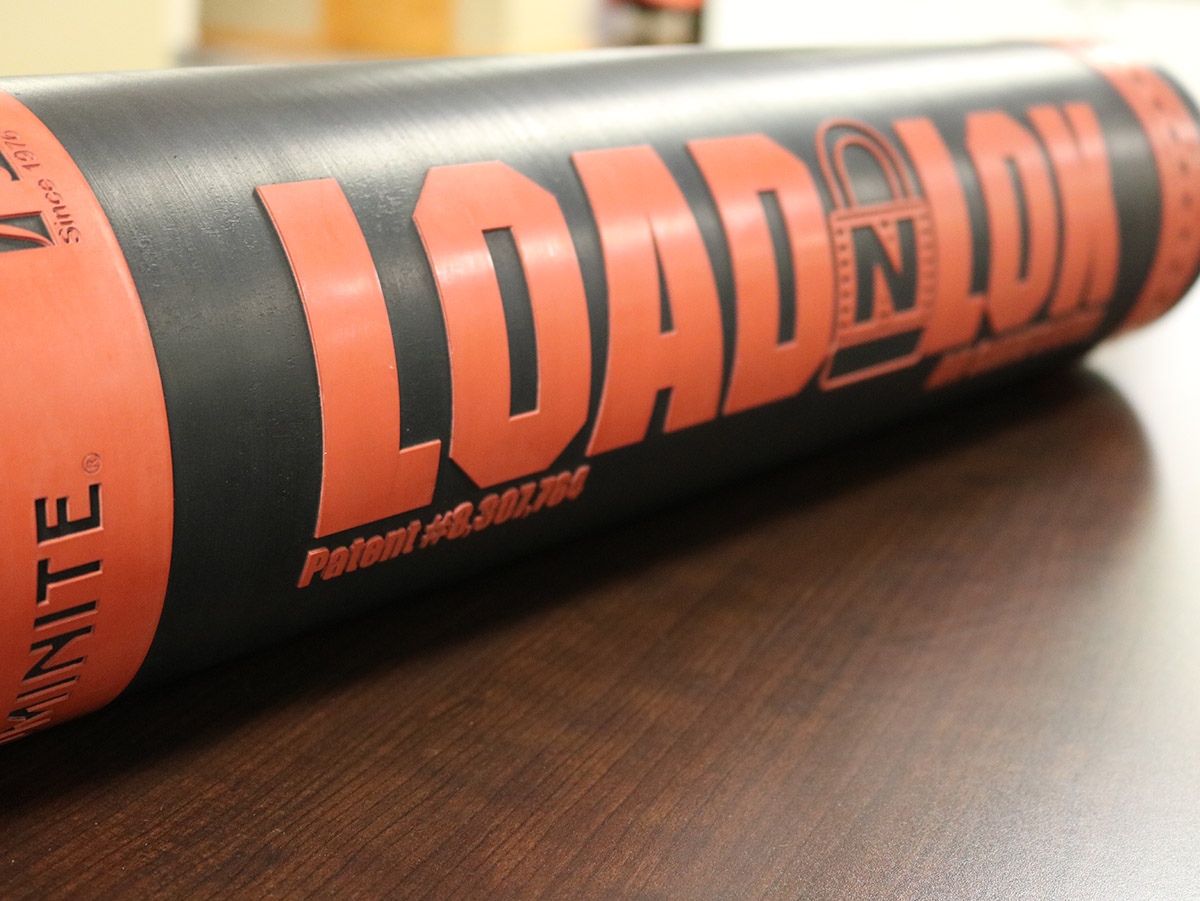

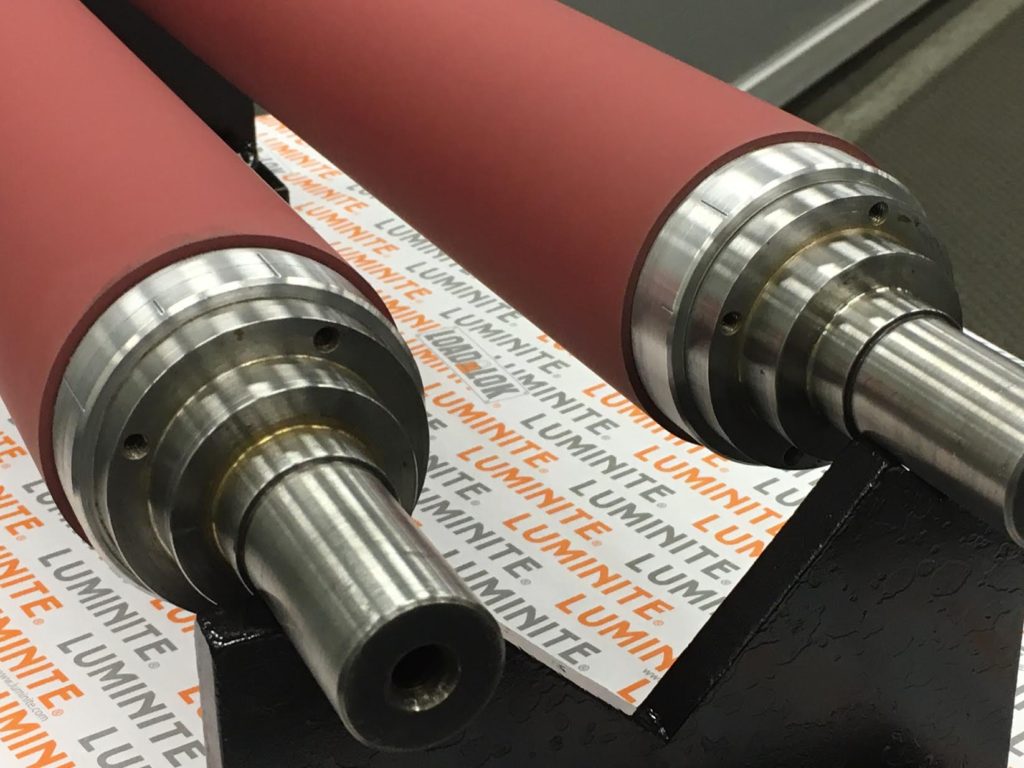

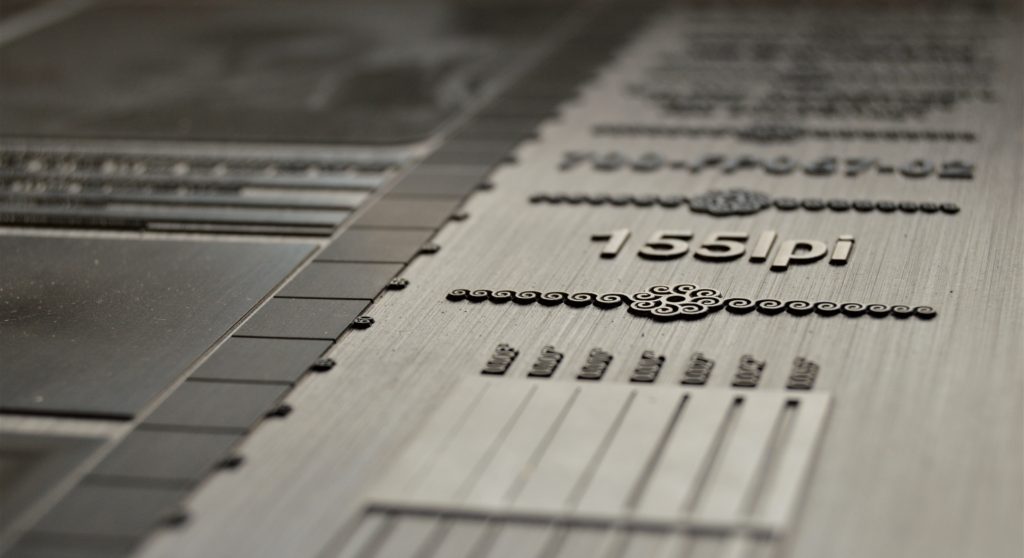

Providing the highest quality products and services for the flexographic industry since 1926 — Luminite Products Corporation offers direct laser-engraved elastomer sleeves, cylinders, & plates for the flexographic printing industry.

Luminite offers the original continuous print solution, with our In-the-round (ITR) technology allowing for a continuous, seamless print. Our elastomer sleeve materials, as opposed to photopolymer sleeves, have greater resilience to combat the rigorous stresses of the printing process.

Support Every Step of the Way

Downloadable Resources

The ultimate comparison guide between flexo printing and offset, litho, digital, gravure, and screen printing. Plus, check out hybrid press considerations and details on corrugated printing.

This popular guide helps you to pinpoint the flexographic printing defect and begin working toward quality solutions. Troubleshoot your problems and reduce press downtime!

Sometimes a one-size-fits-all solution isn’t enough to optimize your prints to the quality that you (and your customers) have come to expect.

Explore everything flexo ink related from viscosity and PH considerations, to the difference between ink type. Learn how to troubleshoot ink transfer problems that arise during printing.

Flexographic Printing Blog

Luminite’s Flexographic Products

Request a Quote

How can we help you deliver quality prints, repeat after repeat?

For additional information or questions please utilize the contact info:

Phone: 888-545-2270

Fax: 814-817-1421

E-Mail: sales@luminite.com