Flexographic Print Cylinders | Elastomer Covered Cylinders

When it comes to flexographic printing, there are multiple materials, technologies, and methods to choose from to ensure a high-quality print. Take, for example:

- Elastomer sleeves

- Photopolymer plates

- Patented Load-N-Lok technology

- Elastomer covered cylinders

Which flexo printing method is right for you? Here’s a bit more about elastomer-covered cylinders.

What Is an Elastomer Covered Cylinder?

Unlike other conventional printing methods, elastomer image carrier products:

- Eliminate unnecessary waste & promote sustainable printing practices

- Decrease setup time

- Reduce cost

- Improve print quality

Depending on the type of print or any customer-specific needs, different varieties of elastomer-covered cylinders may be necessary. Printing cylinder manufacturers should be able to provide:

- Coating/flood coat cylinders (& sleeves)

- Pressure cylinders

- Backup cylinders

- Ink pickup and transfer cylinders

- Hot and cold stamp cylinders

- Tinting cylinders

Elastomer Covered Cylinders | Flexo Printing Applications

Much like elastomer sleeves or photopolymer plates, elastomer covered cylinders work on a variety of substrates, for a variety of applications.

- Flexible packaging

- Labels

- Pressure-sensitive materials

- Embossing

- Hot-melt adhesives

- School / office

- Tissue / non-woven

- Gift wrap / ribbons

- Shrink products

- Medical & pharmaceutical

- Corrugated

Flexographic Printing Cylinder Considerations:

At Luminite, we can produce seamless, in-the-round (ITR) flexographic cylinders that are laser-engraved to meet your specific needs.

To provide optimum print quality, all integral shafts and cylinders to be engraved at Luminite must be received in balance. Out-of-balance cylinders must be balanced to Quality Grade G 2.5 at 2500 RPM before processing.

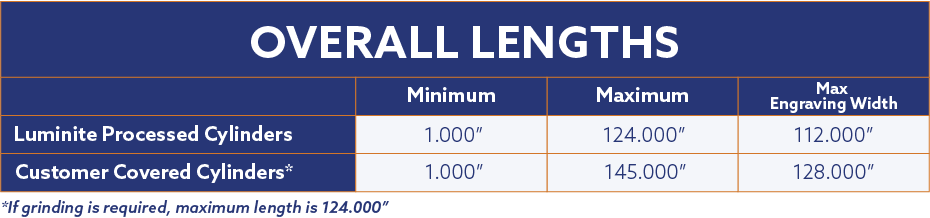

Our capabilities include:

.jpg?width=150&height=150&name=post1-150x150%20(1).jpg)