Our Heritage

Luminite from the Beginning

Luminite Products Corporation was founded in 1926 by Salamanca, NY community and industrial leaders, with William M. Greene as the Secretary of the Corporation and General Manager of the plant. Mr. Greene was the great-grandfather of John F. Vosburg III, present owner and President. The principal impetus of this new company was the acquisition of a newly invented aluminum alloy – called Luminite – which, unlike pure aluminum, was eminently machinable. These cylindrical aluminum bases were cast and machined in Luminite’s own foundry and machine shop. This material, together with engraving machines designed and built by the Company, enabled Luminite to provide relief-engraved printing cylinders that were new to the printing market. The principal users of this product were wallcoverings, draperies, and gift wrap manufacturers. Luminite was the nation’s first full-scale manufacturer of mechanically engraved aluminum printing cylinders.

During World War II, Luminite supported the war effort by manufacturing aluminum and brass parts for fighter planes, machine guns, and tanks. After the war, under the leadership of John F. Vosburg Sr., Luminite expanded the fields of its mechanically engraved aluminum print cylinders with much larger diameter rolls for scenic wallpaper murals, draperies, and other decorative fabrics.

In the 1960s the Company added to its offerings acid-etched and chrome-plated magnesium cylinders, which provided finer designs with much quicker turnaround times to the same markets.

In the early 1970s, it became apparent to John F. Vosburg, Jr., owner and president at the time, that the printing process in which these metal cylinders were utilized was being supplanted by other processes and that the Company needed to acquire new state-of-the-art technology and expand its product line.

In the mid-1970s, Luminite became the first manufacturer in North America to produce and sell continuous laser-engraved rubber-covered cylinders both to wallcovering printers and to an increasing number and variety of other customers in the flexographic printing industry. As a result of this new product and markets, sales volume and employment from 1976 to 1980 nearly doubled.

In 1996, Luminite was issued a patent for improving the performance of nickel sleeves by coating the outer surface and ends with a high durometer elastomer, known as NickeLok (Patent # 5,577,443).

In 1997, Luminite became one of the first laser engravers in North America to convert to digital direct laser engraving.

On September 1, 2001 Richard F. Songer was appointed President and CEO of Luminite by John F. Vosburg Jr.

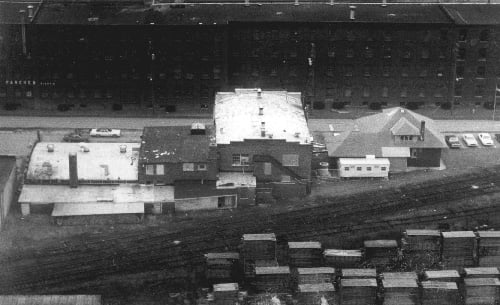

On May 10, 2010, Luminite suffered a great loss when its historical office building was destroyed by a fire. Over the next year and a half Luminite designed and built a brand new 45,000-square-foot facility in Bradford, PA. In our current building, we salvaged the white Luminite sign and used the remaining bricks from the old building seen in our entryway.

In October 2011, Luminite moved the entire company from Salamanca, NY, to their new facility. This marked the first time in 36 years that Luminite’s manufacturing and office personnel would be united under one roof.

In September of 2012, Luminite was granted a patent for a revolutionary new “air sleeve” which is fittingly named Patented Load-N-Lok. Unlike traditional sleeves that require an air mandrel, the new air sleeve can be mounted and positioned anywhere on a plain “airless” mandrel saving time and money. Luminite is the oldest and most recognized manufacturer of continuous laser-engraved printing cylinders in North America. The quality and breadth of products and materials that Luminite offers greatly exceeds the capabilities of all competitors.

.jpg?width=266&height=200&name=locknload%20(1).jpg)