Flexo Printing Solutions:

Industries and Markets Served

Flexographic printing, in its simplest form, has been around since the 19th century. Then, it was basic rubber stamping. As technology has grown, flexo has become more refined, outpacing many other printing methods.

Flexographic printing uses elastomer sleeves or other image carriers to transfer an image onto various substrates such as cardboard, plastic, foil, or paper. This cost-effective printing method can achieve high speeds, maintain accuracy, and efficiently produce large print runs.

Flexible Packaging

Luminite is currently working with most of the top flexographic printers. We are seeing excellent results across a wide range of flexographic printing environments, covering all current inks, substrates, and presses. Whether it’s sleeves, covered cylinders, or plates, Luminite delivers the right product, at the right price, at the right time.

- Seamless repeats / Continuous print

- Ease of registration between ITR and plates

- Decades of flat-top technology for fine screen work

- Distortion free

- Surface tension testing allows us to identify optimum ink transfer properties

- No limit on substrate materials with our range of elastomer compounds

- Ease of registration

- Quicker change over compared to plates

- Less start-up waste

- Patented Load-N-Lok option allows more use of sleeve without an air mandrel

- Sleeves can be reused for multiple jobs

- Layout

- Proofing

- Seamless Textures

- Graphic Design

- Design Consultations

- Color Management

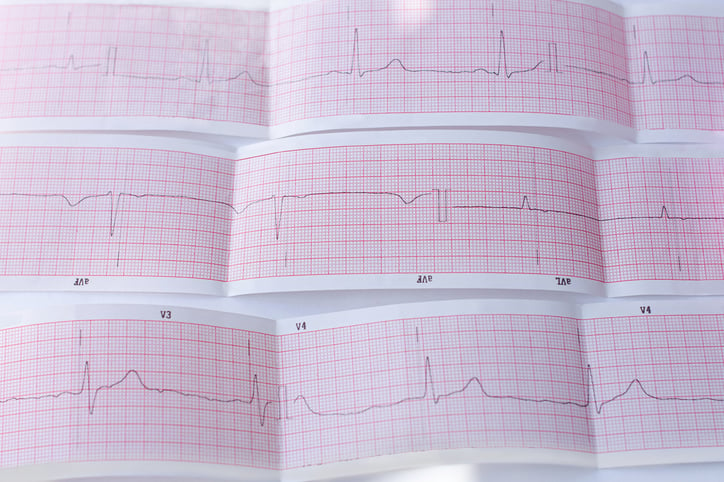

Medical and Pharmaceutical Packaging

Luminite is the market leader when it comes to solving the many challenges facing the medical and pharmaceutical industries. For years we have been successfully assisting major companies around the world creating accurate medical charts and graphs with the fine detail needed for precise calibrations and reliable readings. Luminite sleeves provide distortion free printing and high repeatability for error-free work, whether it’s for medical charts or pharmaceutical packaging materials.

We also provide products that allow you to lay down high temperature adhesives allowing accurate positioning for worry free packaging for all types of medical products.

- Reliable and exact measurements using our digital direct laser engraving technology

- Text point size as small as 0.75 pt for basic non-serif fonts

- Screens for gradients, vignettes, and 4 color process up to 175 line

- Superior transfer of ink compared to photopolymer plates and sleeves

- Distortion free

- Can be used on many different substrates

- Worry-free accuracy on repeat orders

- High-temperature applications

- Seamless blanket sleeves are also available

- Can be used with direct (flexo) and indirect (offset) printing

- Quicker change over compared to plates

- Seamless printing, eliminating plate bounce, and lessening registration issues

Food Packaging

The goal of food packaging is to be both enticing and safe at the same time. Packaging designers must use FDA-compliant materials to minimize the risk of food contamination from inks or the substrate.

Just because food packaging designers need to take extra precautions doesn’t mean their packaging still can’t be bright, vibrant, and attractive.

Using in-the-round printing solutions like elastomer sleeves can really make food packaging pop when they’re on the supermarket shelf.

- No distortion

- Elastomer printing products are long-lasting

- Easy setup

- Comprehensive material selection – chemical compatibility with inks and substrates

- Integration with any press

- The most consistent print register

- Decades of industry experience

School, Home, and Office Products

.jpg?width=724&height=483&name=iStock-1463810084%20(1).jpg)

Notebook paper, steno books, and index cards all require consistent ruling and printing to create a uniform product. Digital direct laser engraved sleeves and cylinders ensure the best print time and time again.

Luminite sleeves and elastomer-covered cylinders are consistently manufactured to give you highly accurate and consistent results for various office products.

- Fine line weights to 0.001″

- Precise stepping and repeats

- Accurate front-to-back registration

- Quads and Graph Paper

- Ability to accommodate numbered lines and date blocks

- Up to 112.000″ engraving width

- Engraved sleeves and cylinders up to 61.842″ repeat/non-engraved up to 77.911″ repeat

- In many cases, we can rework sleeves multiple times for cost savings

- Sleeves are easy to handle, store, and load on your press

- Decades of experience with ruling projects

Consumer Products – Tissue/Non-woven

Many types of patterned paper towels, tissue papers, and napkins are printed on using flexo printing and elastomer sleeves. Luminite sleeves can produce print widths of up to 110.000” with repeats up to 60.000”. Sleeves allow for greater flexibility in printing across multiple lanes with no distortion, increasing productivity on each press run.

- Seamless repeats, continuous print

- Easier registration with existing sleeves and plates

- Flat top dots allow for finer detailed screen work

- We measure surface tension and customize rubber formulation for optimal ink transfer

- No distortion

- Sleeves are easy to handle, store and load on your press

- Conceptual art available on request

- Elastomer typically outlasts photopolymer in most applications

Custom Shipping Materials

.jpg?width=724&height=483&name=iStock-1159610737%20(1).jpg)

As consumers become more aware of the packaging their products come in, brands are paying more attention to their shipping materials as well. Think about corrugated shipping boxes with brand logos as well as special paper tape, like the Amazon Prime tape used for Amazon packages.

Flexographic printing excels at printing on corrugated cardboard, and elastomer sleeves help to improve image quality and repeatability, making your shipping materials stand out.

- Elastomer sleeves are well equipped for printing on corrugated packaging

- High-quality images

- Tight tolerances on diameter and TIR result in a lighter, less damaging impression

- No seam lines

- Capable of using a wide array of inks

- Paper, plastic, or film tape printing capabilities

- Decades of industry experience